Meet Titanus.

The Powerhouse.

Engineered for extreme loads. Titanus is the 1500kg payload autonomous robot designed to transport pallets, large bins, and heavy machinery components in complex industrial environments.

1500 KG

Max PayloadMulti-Module

Pallet / Bin / Roller24 Hrs

Runtime

Why Deploy Titanus?

Delivering measurable improvements in throughput, safety, and ROI for heavy industrial workflows.

Maximize Throughput

Eliminate bottlenecks. Titanus operates 24/7 without breaks, keeping your production lines fed and finished goods moving instantly.

Workforce Optimization

Stop using skilled humans for manual hauling. Redeploy your staff to high-value assembly and quality control tasks.

Reduce Operational Costs

Lower your reliance on expensive manual forklifts and significantly reduce product damage caused by human handling errors.

Zero-Incident Safety

Titanus is safer than a forklift. Its advanced sensors detect people and obstacles instantly, reducing workplace accidents to near zero.

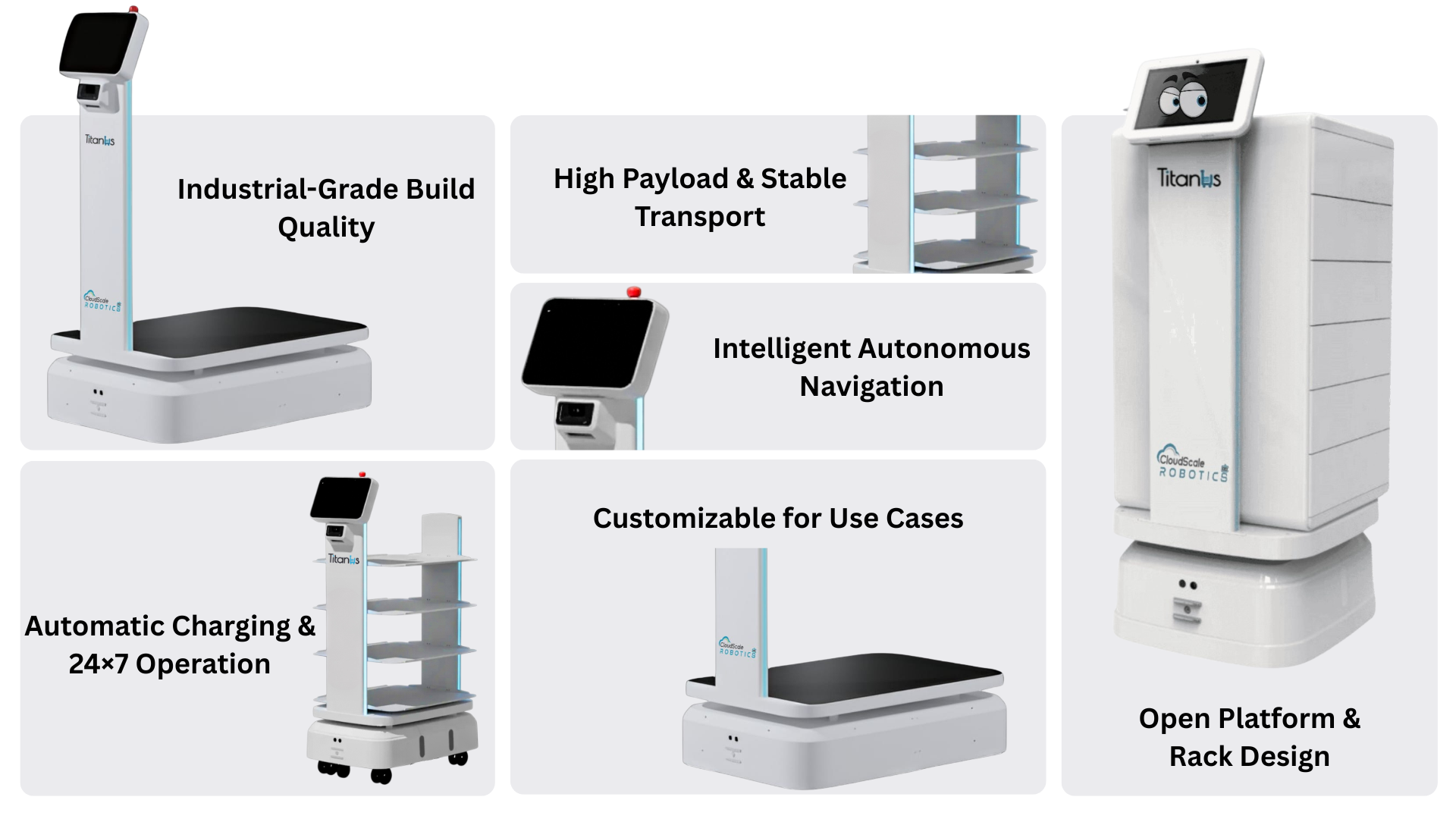

One Robot. Endless Possibilities.

Titanus features an open chassis design, allowing for seamless integration of shelves, bins, rollers, or custom modules.

Select Your Capacity

From compact shelving units to heavy-duty flatbeds. Choose the Titanus model that fits your facility.

T-80

T-150

T-300

T-300E

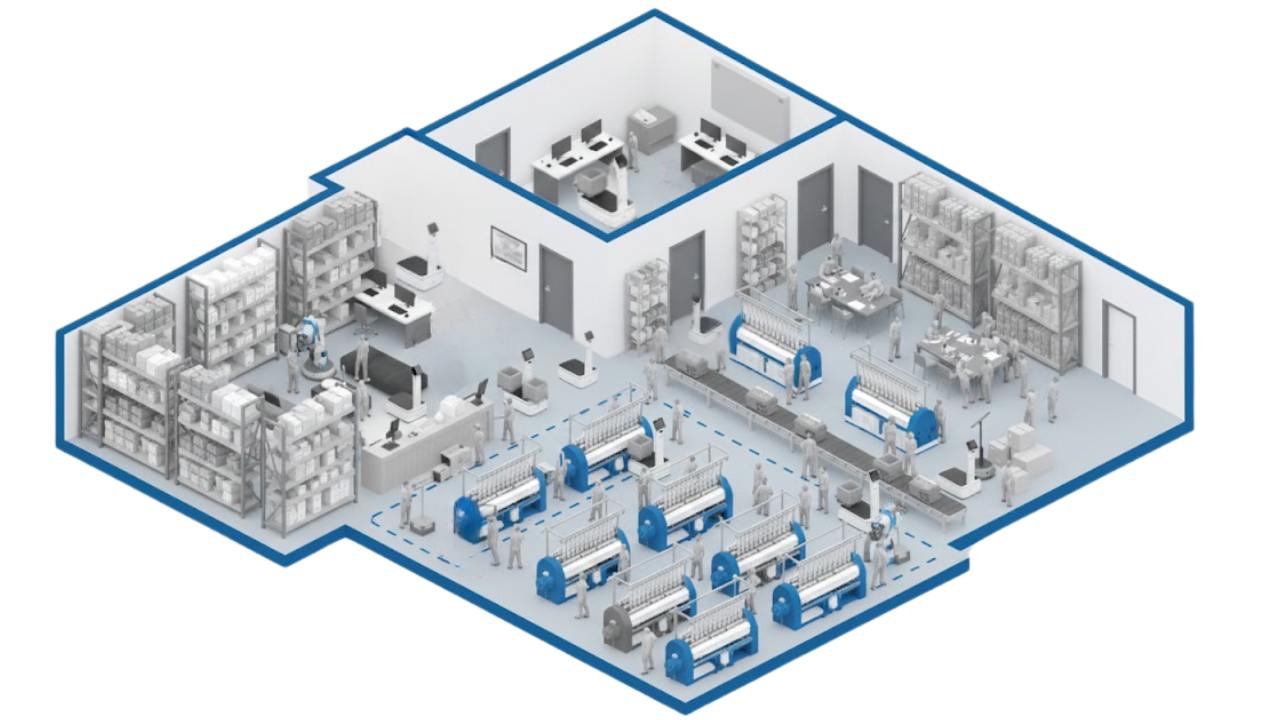

Mastering Complex Environments

See how Titanus adapts to different industrial tasks, from narrow storage aisles to busy assembly lines.

Narrow Aisle Inventory

Titanus is designed with a compact footprint to navigate tall, narrow warehouse racking aisles where standard forklifts struggle to fit.

- Centimeter-level positioning accuracy

- Safe operation near static racks

- Optimizes vertical storage density

Precision Line Feeding

Titanus integrates directly into active assembly lines. Here, it follows a precise path (yellow line) to deliver raw materials to workstations, keeping human operators focused on assembly.

- Just-In-Time (JIT) material delivery

- Reduces worker walking time

- Follows dynamic production schedules

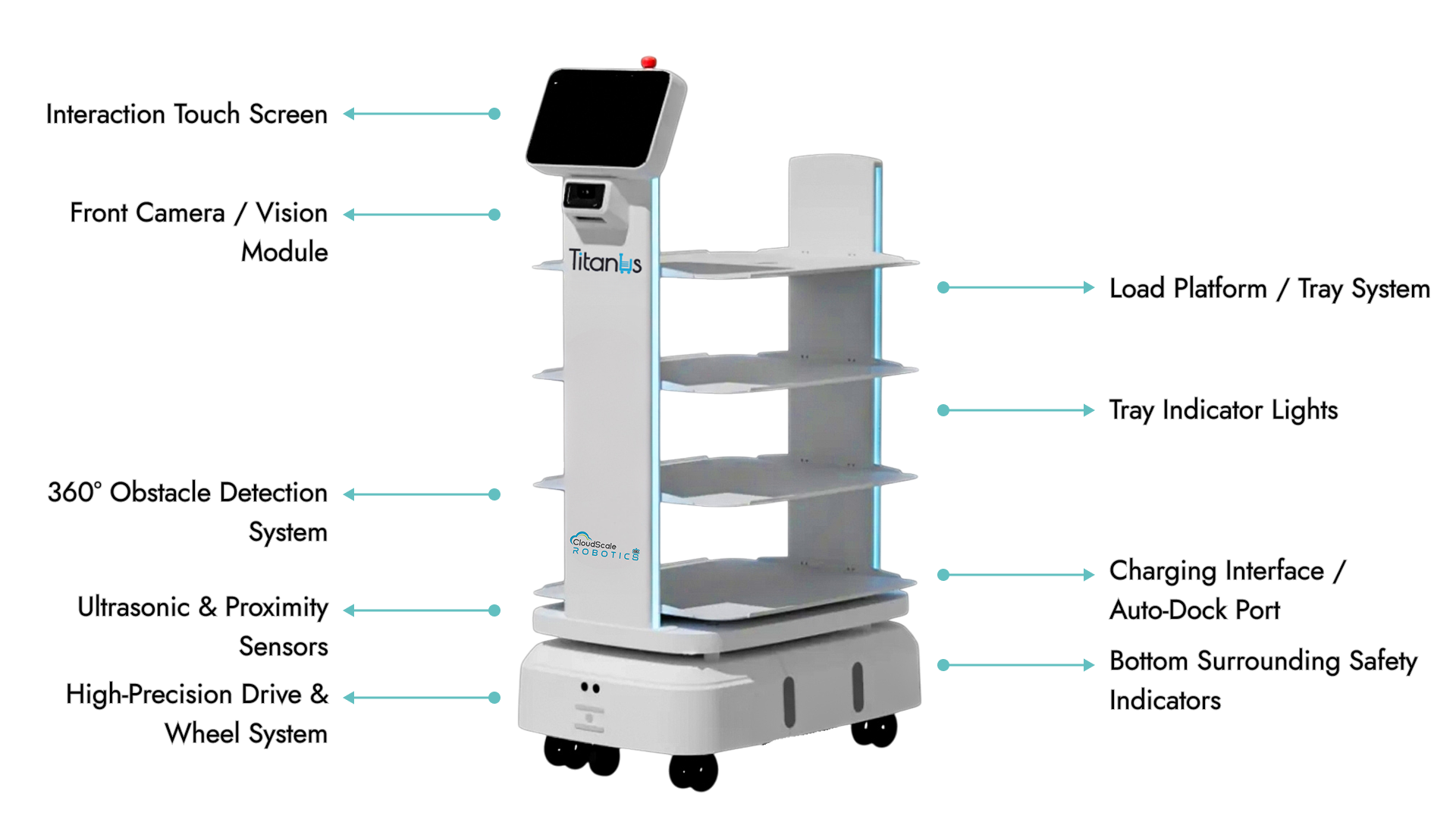

Assisted Workstation Delivery

Seamless human-robot collaboration. Titanus delivers kits directly to the operator's hand. The intuitive touchscreen and LED indicators let staff know exactly when a delivery has arrived.

- Ergonomic tray height for easy unloading

- Visual status indicators (LED lighting)

- Safe stop proximity sensors

Heavy Industrial Transport

Built for the toughest environments. The enclosed Titanus unit (shown here) protects sensitive payloads from dust and debris while navigating through heavy machinery zones.

- Enclosed chassis for load protection

- Operates in high-dust environments

- Secure transport for valuable components

See Titanus in Action

Watch how Titanus navigates complex facility layouts and handles heavy payloads with ease.

The Backbone of

Heavy Industry

Titanus isn't just a heavy lifter; it is a connected logistics terminal. It utilizes advanced **Laser SLAM** to map massive industrial floors without blind spots.

From raw material intake to final shipping docks, it unifies traffic control, integrates with elevators/auto-doors, and syncs tasks directly from your WMS or ERP server.

Engineered for Versatility & Scale

An open industrial chassis designed to adapt to various heavy-load modules and configurations seamlessly.

Full Fleet Specifications

Comprehensive performance data for the Titanus D-Series delivery robots.

| Feature / Model | T-80 | T-150 | T-300 | T-300E |

|---|---|---|---|---|

| Physical Dimensions & Capacity | ||||

| Max Load Capacity | 80 kg | 150 kg | 300 kg | 300 kg |

| Dimensions (mm) | 570×500×1240 | 740×500×1240 | 740×500×1240 | 900×600×1240 |

| Loading Area (mm) | 500×424 | 580×500 | 620×500 | 770×600 |

| Empty Vehicle Weight | 65 kg | 90 kg | 85 kg | 95 kg |

| Min. Passage Width | 60 cm | 70 cm | 70 cm | 80 cm |

| Screen Size | 10.1 inches | 10.1 inches | 10.1 inches | 10.1 inches |

| Performance & System | ||||

| Maximum Speed | 1.2 m/s | |||

| Navigation Method | Free Navigation / Track Navigation / Hybrid Navigation / Follow | |||

| Positioning Accuracy | 10 mm | |||

| Network | 4G / Wi-Fi | |||

| Battery | 12h endurance, 5h charging | |||

| Certification | CE / FCC / KC / NCC / EMC | |||

| Expandable Peripherals | Elevator, automatic door, notification lights, speakers, call buttons, follow bracelets, rollers, cabinets, shelves | |||